HACCP Restaurant: Free yourself from HACCP

By choosing EEat and its HACCP application you can:

✅ Automate the temperature control of your cold chambers.

✅ Take delivery of your goods in a few clicks.

✅ Ensure the traceability of your products.

✅ Ensure standardised HACCP training for your staff.

✅ Keep track of cleaning and say goodbye to oversights.our staff.

EEat supports restaurants in the daily application of the HACCP (Hazard Analysis Critical Control Point) method. Simplify the monitoring of regulatory requirements for hygiene procedures, food safety and food traceability.

EEat adapts to your restaurant

With EEat, you can control health hazards and guarantee the food safety of your customers.

A simplified traceability of foodstuffs designed for restaurants

Free yourself from the burden of monitoring cold chamber temperatures

Achieve 100% compliance with your sanitary control plan

The HACCP regulation

What do the regulations say about restaurants?

All restaurants must implement the HACCP (Hazard Analysis Critical Control Point) method to control health hazards and risks.

The HACCP method consists of implementing critical control points (CCP) and their associated corrective measures.

Swiss 🇨🇭 and European 🇪🇺 regulations require at a minimum the following critical points to be in place:

- ❄️ the control of food storage temperatures

- 🧽 a cleaning plan

- 🚛 the control of incoming goods

- 🏷 the conservation of raw materials’ labels

In order to be 100% compliant with the regulations, we recommend carrying out a hazard analysis to ensure the implementation of the correct self-checks.

This hazard and risk analysis must take into account chemical, physical and biological hazards.

HACCP training for staff is an essential part of the sanitary control plan (SCP). With HACCP training courses, each employee must be able to apply the HACCP method and carry out the critical control points.

How to implement the HACCP method in your establishment

Download your free HACCP workbook

Automate the temperature readings of your refrigerated chambers

The catering industry involves working with different food products that each have their own storage conditions to preserve quality. But what they have in common is the obligation to respect the cold chain to guarantee a healthy product for the consumer.

The control and monitoring of the cold chain is a key element of the HACCP method. This implies tracking and regularly monitoring the temperatures of the cold chambers of your establishment: it is the principle of the storage temperatures’ self-check.

Temperature reading self-checks are highly time-consuming. Moreover, they do not enable the effective detection of a breakdown or malfunction of installations, as stored goods are often already lost when a problem is detected.

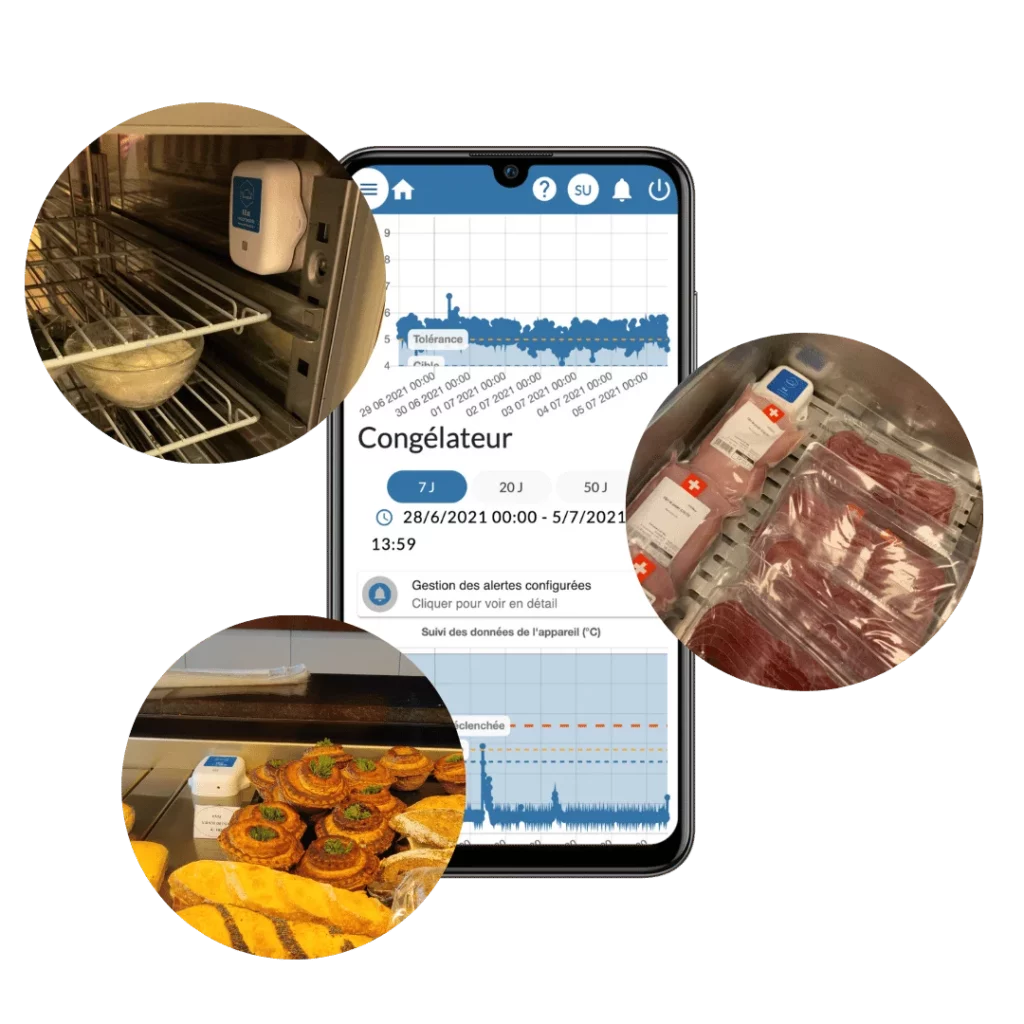

EEat has developed a solution to free restaurant owners from the burden of temperature reading self-checks. Thanks to our connected sensors, you can automate temperature readings (measurements are taken automatically at regular intervals). If a measured temperature is out of range, you are immediately alerted by email or SMS, and you can take the appropriate corrective measures. This way, you prevent any risk of breakdowns, but more importantly of loss of goods.

The EEat sensors work in both positive and negative cold. The frequency of the temperature readings can be set to suit your needs (every hour, every 15 minutes, once a day, etc.). It is a wireless sensor that you install directly in your freezers, cold rooms, etc.

By automating your temperature readings you save an average of 1 hour per week in the management of your food hygiene standards (registration, storage and hazard analysis).

EEat and its temperature sensors allow all restaurants to easily and inexpensively have access to a solution that guarantees the safety of food stored in refrigerated chambers at all times.

Digitise the production of your labels

Regulations require restaurant owners to keep all the labels of the food products they use to cook their dishes. These labels ensure the traceability of foodstuffs in the event of the food poisoning of a consumer. This traceability allows the chain of composition to be quickly traced and the products or batches that present a risk to the consumer to be isolated.

This requirement is often complex for restaurants to manage, especially in terms of archiving, as the storage conditions for labels range from several days to several months depending on the product. Labels are often stored in filing cabinets that end up taking up a lot of space. In the event of a suspected poisoning or a control by the authorities, this method of storage requires painstaking searches in order to find the necessary labels. In addition, the labels can often be smeared with various stains. Storing them in a kitchen is thus rather unhygienic.

With EEat and its digital label storage solution, you are freed from the constraints of paper archiving. When you use a product, you can directly scan the label with the camera of your tablet or smartphone, and it will be immediately saved on our secure servers in Switzerland and available at any time from any device (computer, tablet, smartphone). You will no longer need to store dirty labels on your premises.

In the event of a state inspection or a possible intoxication, you can find with just a few clicks the labels of the foodstuffs used during the concerned period: no more endless searches.

At EEat, thanks to our connected printers, we have also developed a secondary labelling module for your raw materials and preparations that allows you to re-label your stock or semi-finished food products. The best-before dates are generated automatically as well as the batch numbers.

Simplify the storage of your foodstuffs’ labels with EEat and its digital traceability solution!

Keep track of your cleaning plan

The HACCP method and food hygiene standards recommend paying close attention to the hygiene procedures of your premises and production facilities. The aim is thus to prevent the contamination of foodstuffs and preparations with unwanted allergens or bacteria due to the production means used by the restaurateurs.

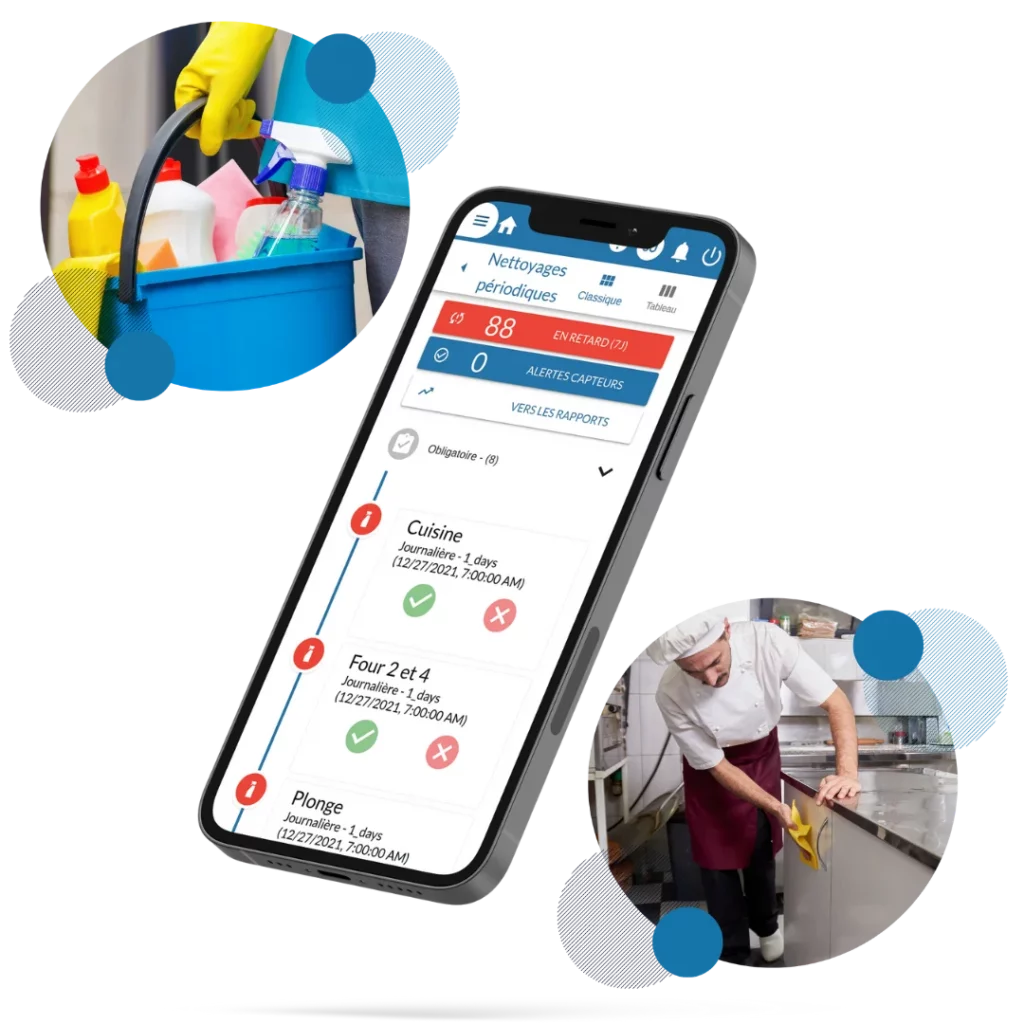

The regulations require a cleaning plan to be drawn up, which specifies the different areas to be cleaned and their cleaning frequency according to the potential risk of their contamination. Each cleaning that is carried out should be logged by the teams, and these records need to be archived.

As with the raw materials’ labels, cleaning plan sheets are often stored in binders which quickly take up space. Moreover, the disadvantage of paper cleaning plans is the difficulty of extracting and analysing information to detect, for example, an oversight in the completion or logging of a particular cleaning. You therefore cannot ensure that the cleaning plan is properly carried out without spending a considerable amount of time on it.

EEat makes it easy for restaurant owners to manage and track their cleaning by creating a digital cleaning plan. You can define the cleaning areas of your establishment and the frequency of their cleaning (daily, weekly, monthly, etc.).

Your employees log the cleanings directly on the EEat application. The information is automatically archived and accessible. If a cleaning is missing, you are immediately alerted so that you can react as quickly as possible.

EEat also allows you to view the logging data from dashboards. This way, you can easily monitor the correct execution of cleaning in your restaurant.

Stop storing paperwork and prevent staff oversights with EEat’s digital cleaning plan!

Connected objects to ensure the quality of your food products

The digital management of your raw materials’ labels

A digital cleaning plan that adapts to your restaurant

With EEat, your restaurant is 100% compliant from CHF 0.50 per day

Discover our self-checks, designed especially for your restaurant:

- Secondary labelling: print your labels in 2 clicks

- Cleaning: record the completion of your cleaning procedures

- Reception of goods: archive and control the quality of your arrivals

- Storage temperatures: relax, the control is automatic

- Control dishes: collect the necessary samples

- Rapid cooling: keep up with the standards and follow the cooling stages

- Traceability: effortlessly manage your incoming and outgoing batches

- Inventory management: keep track of your products in real time

- Cooking temperatures: keep a record of your cooking processes

- Pest control: regularly check the hygiene of your premises

EEat can be implemented in 3 steps

1

You send us your current self-checks, we digitise them. You don’t have any self-checks in place? We can advise you. Do you have your own processes? We can customise our system. Just contact us!

2

Would you like connected sensors? We can send you the sensors and our EEatbox to collect the data. Just follow our instructions to install it within minutes.

3

You install our haccp app on the device of your choice (computer, tablet, phone) and you can free yourself from HACCP!